ITC Coatings

Background

Material Supply Details

ITC's most versatile ceramics coatings that has proven to achieve outstanding energy savings and refractory protection. It is installed mills thick as it can be used solely by itself or as a final top coat over other ITC products such as ITC 213.

An outstanding ceramics coatings for metal. It is formulated to protect metals and graphite surfaces including those exposed to molton metals before the final coat is applied.

A high purity ceramic top coat that gives a clean firing and minimizes impurities in gloss kilns and molten metal operations. It will prevent dross, slag build up, heavy suds, and carbon deposits.

ITC’s only ceramic fill product. It is proven to be an excellent durable compound and most versatile ceramics coating. Over the years it has been shown to repair broken, chipped or cracked brick and castable or fiber material. It bonds rapidly and eliminates the need for costly rebricking which saves on down time.

ITC's key heavy duty ceramic repair product formulated to protect metals and graphite, including those exposed to molton metal. It also prevents stainless steel and steel parts from erosion, oxidization, and fatigue.

Superior Results

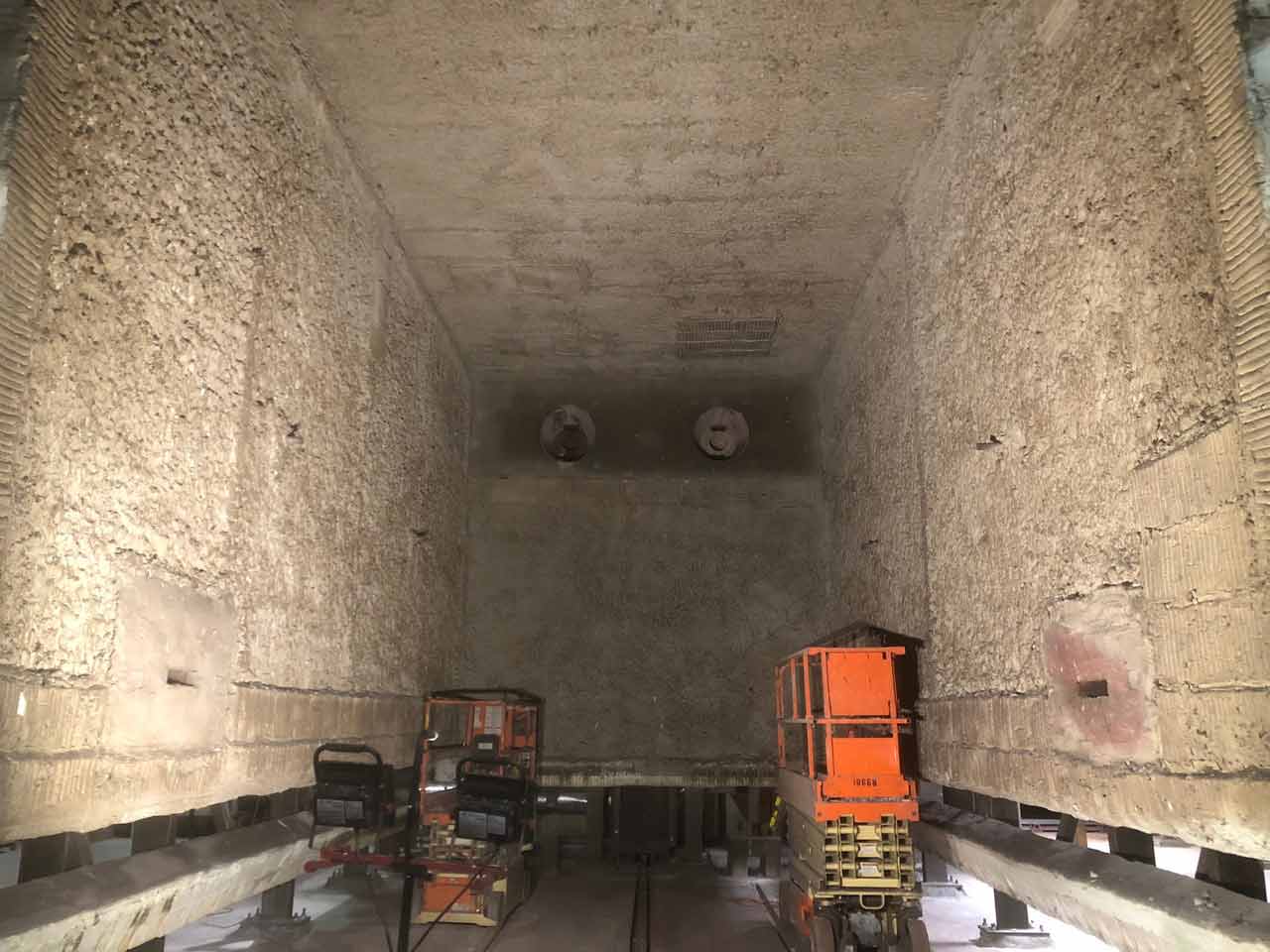

Examples of Applications